Method for making colored asphalt pavement

The raw material fo colord asphalt

The raw material and processing is similar to to traditional black bitumen. The main raw material for colored asphalt are including : crushed stone, asphalt pigment powder and decolorized asphalt oil.

Crushed Stone

Asphalt Pigment Powder

Decolorized Asphalt Oil

Samples From The Lab

The difference between colored asphalt and black bitumen

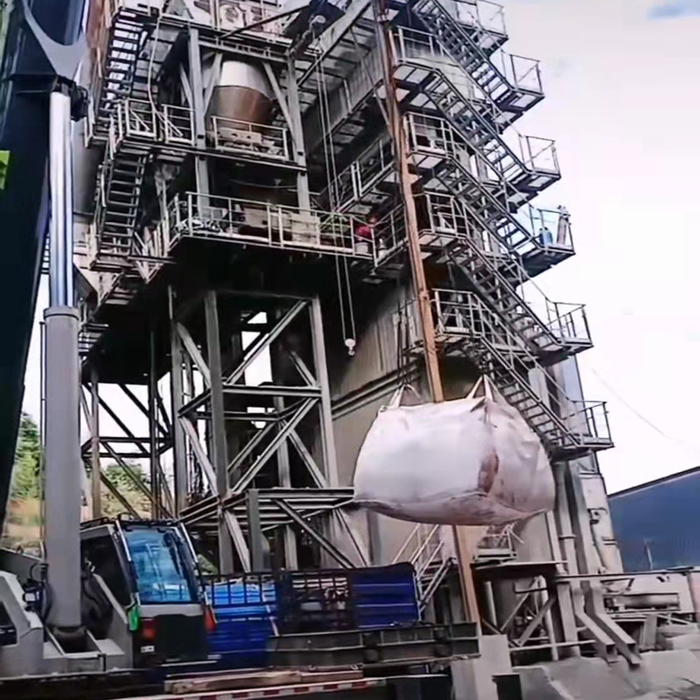

The process and the facility is very similar with the black bitumen.

A:The difference is about the temperature, different color, the temperature will be different.

B: At meanwhile we will use the colored pigment powder to replace the mineral powder.

C: We will use the decolorized asphalt oil instead of the black bitumen.

Color asphalt production process

Heat a fixed amount of crushed stone to target temperature(such us: 130-150℃ for blue asphalt), add 3% of pigment powder and 5% of discolored asphalt oil in proportion, stir evenly, maintain the temperature in 130-150℃ in the mixing process, and then spread and compacted.

|

Pigment Name |

Area |

Thickness |

Crushed Stone Density |

Crushed Stone Weight |

Material Addition ratio |

Material Weight |

Temperature Range |

|

Asphalt Pigment Red |

1000 |

5 |

2.35 |

117.5 |

2.50% |

2.94 |

140-170 |

|

Asphalt Pigment Yellow |

1000 |

5 |

2.35 |

117.5 |

3.00% |

3.53 |

130-150 |

|

Asphalt Pigment Green |

1000 |

5 |

2.35 |

117.5 |

3.00% |

3.53 |

130-150 |

|

Asphalt Pigment Blue |

1000 |

5 |

2.35 |

117.5 |

3.00% |

3.53 |

130-150 |

|

Asphalt Pigment Gray |

1000 |

5 |

2.35 |

117.5 |

2.50% |

2.94 |

130-150 |

|

Asphalt Pigment Orange |

1000 |

5 |

2.35 |

117.5 |

2.50% |

2.94 |

130-150 |

|

Discolored Asphalt |

1000 |

5 |

2.35 |

117.5 |

5.00% |

5.88 |

130-150 |

Discharging after Stir and Heat (Red)

Spread (Red)

Compacted (Red)

Discharging after Stir and Heat (Blue)

Spread (Blue)

Compacted (Blue)